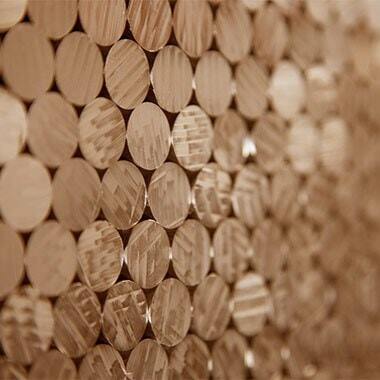

Anticorodal Bar

EN AW 6026

The main applications for turning, electrical applications, and the automotive industry.

An innovative alloy that meets all environmental requirements. Alloy 6026 represents a perfect compromise between the high workability of alloy 2011, and the suitability for anodic oxidation of the 6000 series alloys. Widely used for hot moulding and high-speed machining on automatic lathes.

TECHNICAL CHARACTERISTICS

- Workability: very good

- Suitability for oxidation: very good

- Hard anodisation: excellent

- Hot plastic deformability: excellent

- Weldability: excellent

AVAILABILITY

The alloy 6026 is available extruded in the physical state T6, and drawn in the physical state T3/T8. Other physical states are available upon request.

GENERAL INFORMATION

Chemical composition (% weight)

| Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Zr | Pb | Bi |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0,60 | 0,20 | 0,20 | 0,600 | 0,50 | |||||||

| 1,40 | ≤0,70 | 0,50 | 1,00 | 1,20 | ≤0,30 | ≤0,30 | ≤0,20 | 0,050 | 1,50 |

Physical properties (state T651, indicative values)

- Specific weight: 2.7 g/dm3

- Density: 2.72 kg/dm3

- Elastic modulus: 69000 MPa

- Thermal expansion coefficient: 23.4 (x10-6/°C)

- Thermal conductivity at 20 °C: 172 (W/mk)

- Electrical resistivity at 20 °C: 0.039 (Ω mm2/m)

MECHANICAL PROPERTIES

Extruded

| Status | Rm MPa | Rp 0,2 MPa | A% | HBW |

|---|---|---|---|---|

| T6 | 370 | 300 | 8 | 95 |

Drawn

| Status | Rm MPa | Rp 0,2 MPa | A% | HBW |

|---|---|---|---|---|

| T6 | 370 | 300 | 8 | 95 |

| T8 | 345 | 315 | 4 | 95 |

| T9 | 360 | 330 | 4 | 95 |

Baratè Spa

Via Alberto Baratè, 5

27036 Mortara (PV), Italy

VAT: 00837850189

ER-0248/2021

CONTACT US!